CNC Glass Edge Grinding Milling Dilling Machine

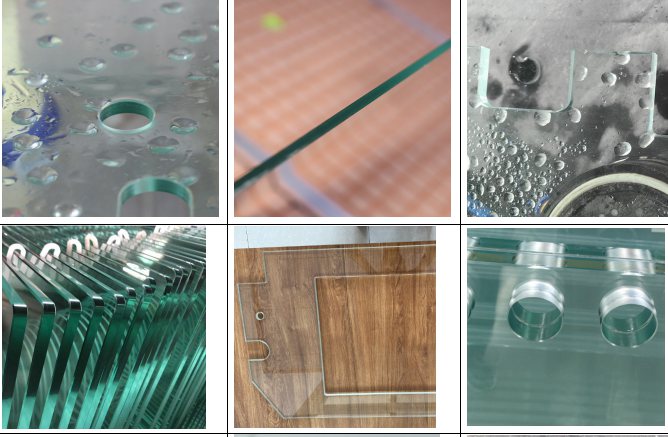

iGA-M CNC glass machining center is a combination of glass edge grinding, chamfering, polishing, drilling, and milling. Specially designed for grinding from the inside or outside, the equipment features simple operation and applies to machining automotive glass, home appliance glass, furniture glass, shower room glass and mirrors of all descriptions. It is aimed at automating production and thus improving the competitiveness of enterprises.

Equipment design is compact, precision assembly, using large inertia servo motor, industrial control system, constant power high-speed electric spindle, three axes are using high-precision rack transmission suitable for high-speed, low-speed and other cutting processing. It has the characteristics of high processing accuracy and stable operation, focusing on the milling forming of specific shapes, such as simple or more complex contour processing such as straight lines and curves, and is usually more focused on shape processing.

CNC Glass Cutting Edge Polishing Dilling Machine

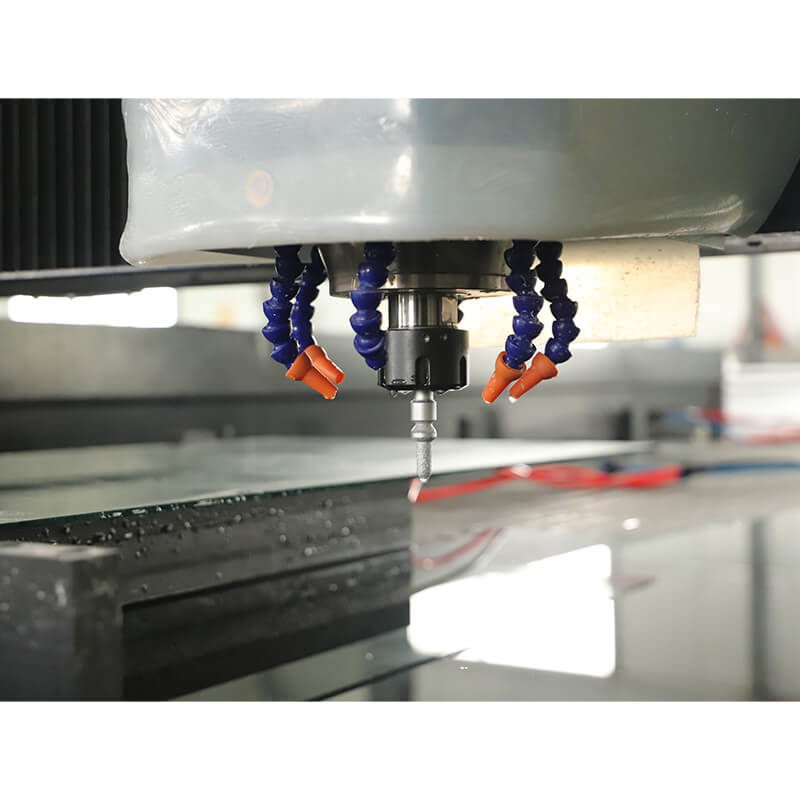

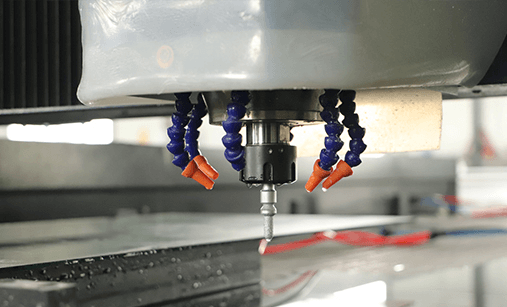

7.5KW water-cooled main shaft

The use of powerful high-power spindle, cutting force, high efficiency, water circulation cooling, good heat dissipation, smooth and fast operation.

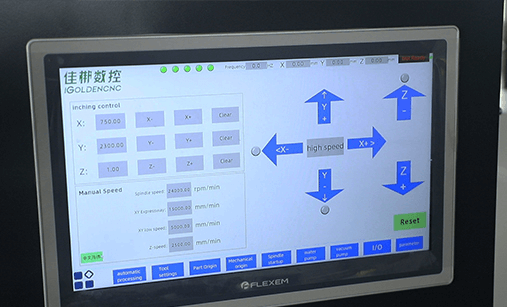

Professional glass operating system

Professional control system, fast and smooth processing, can be cut, drilling, hinge, shaped cutting, edging, glass polishing and other processing.

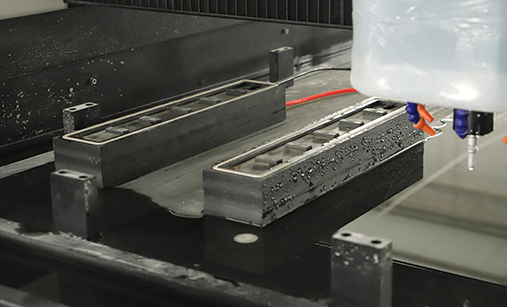

Loading and unloading rollers

Aluminum alloy cylinder, hard oxidation, good sealing effect, high efficiency, reliable positioning, long service life.

Glass adsorber

Standard: 2 vacuum adsorption plates +2 circular suction cups, high vacuum, large suction.

CNC Glass Cutting Dilling Machine

| Technical indicators | parameter |

| Model | iGA-M1025 |

| Work trip | 1000mm*2500mm*200mm |

| Overall dimension | 1900mm*3600mm*1600mm |

| Weighted bed | Thick wall square pipe welding |

| Control system | Glass drilling and milling special system |

| Spindle | 7.5kw drilling and milling special spindle |

| Spindle speed | 0-24000 rpm |

| Machining thickness | 3-19mm |

| Frequency changer | Bester inverter |

| Drivers and motors | DORNA servo motor (X-axis Y-axis 1.5KW, Z-axis 750W with lock) |

| Work surface | 3mm steel plate +25mmPVC plate |

| Reduction gear | SHIMPO |

| Rack | High precision grinding rack 1.5m |

| oiling | Manual oiler |

| Repeated positioning accuracy | 0.025mm |

| Glass fixing system | Standard configuration:2 vacuum adsorption plates +2 circular suction cups |

| Operating voltage | 380V |

| Loading and unloading | Auxiliary pulley |

| Electrical component | Omron |

Benefits of CNC Glass Cutting Centre

Cnc Glass Cutting Machine Application

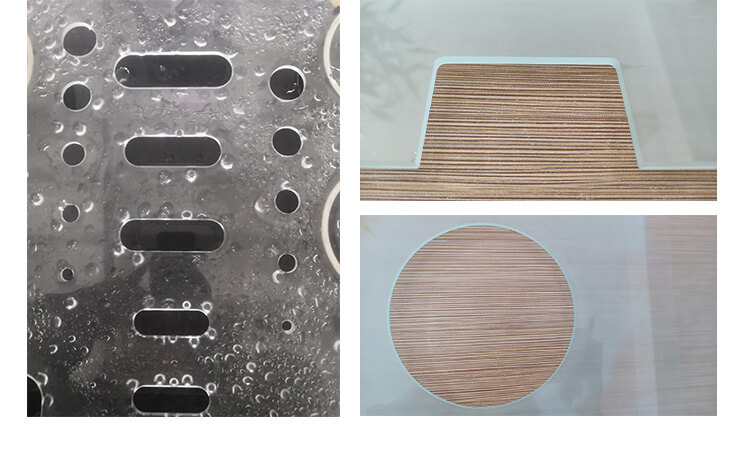

Cnc Edging Polishing Milling Glass Cutting Machine ,Drilling, Milling, Internal and External grinding and polishing, Writing, Shaped Notching, Engraving on glass、Marable, stone, quartz and so on.

1. Edging and polishing of electrical panel glass.

2. Electronic scale glass3. Furniture glass.

4. All kinds of special-shaped glass edging and polishing.

5. Various shapes of tea table glass and tea table rock slabs, various edge grinding.

6. Glass round table edging.

7. Cupboard glass door panel, wardrobe door panel edging.

8. Edging and polishing of hood stove panel.

9. Induction cooker glass ceramic edging

10. Glass edging for cars.