4×8 Wood CNC Router

A Wood CNC Router can cut and shape wood with incredible precision. Whether it’s cutting intricate patterns, creating joints, or shaping curved edges, these machines can handle a wide range of woodworking tasks.

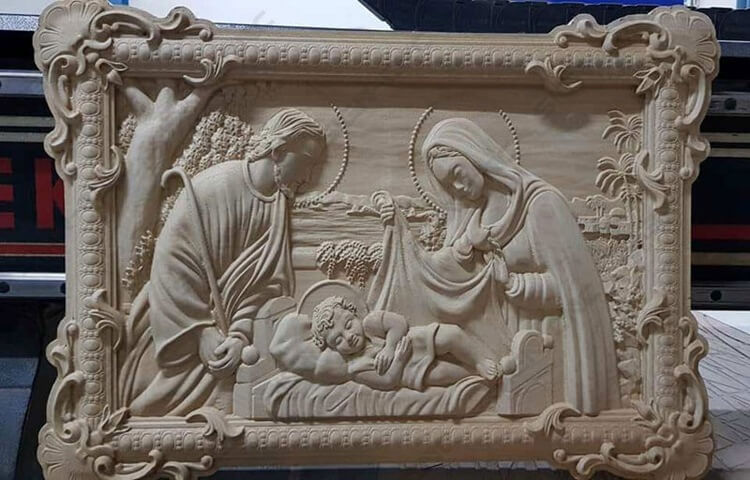

With the ability to control the depth of cut, a Wood CNC Router is perfect for engraving and carving intricate designs and patterns onto wood surfaces. From personalized signs to detailed artwork, these machines can bring creativity to life.

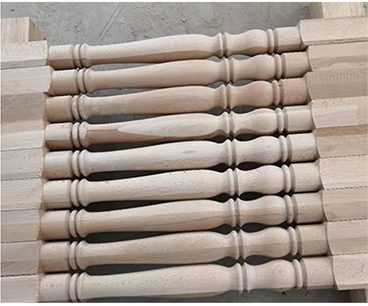

4th axis, is a specialized machine that adds rotational movement to the traditional X, Y, and Z axes. This additional axis allows the cutting tool to rotate around the workpiece, enabling woodworkers to create intricate three-dimensional designs and perform complex operations that were previously challenging or impossible.

3D Sculpting: Advanced Wood CNC Routers can perform 3D sculpting, allowing woodworkers to create three-dimensional objects and sculptures. These machines can carve intricate details and textures, bringing depth and dimension to woodwork.

Used for carving, cutting wooden furniture, gifts, crafts, advertising signs and so on. Other options can be added according to different production processes, such as spindle swing, side rotation axis, etc.

4x8 Wood CNC Router

Wood CNC Router Parameter

| Model | iGW-ATC |

| Working area | 1300*2500*200mm |

| System | LNC 4-axis system |

| Cabinet | LNC Cabinet |

| Beam | Steel Gantry |

| Countertop | Vacuum suction can suck and clamp the countertop |

| Rail | Taiwan HINWIN |

| Spindle | 9KW HQD air cooling spindle ( swing 180°) |

| Drive | Dongling 1.5KW |

| Frequency conversion | Fuling 11KW |

| Voltage | 3phase 380V/60HZ |

| Motor | X/Y axis: Dongling Servo 1.5KW + SHIMPO reducer. Z axis: Dongling Servo 1.2KW + brake |

| Rack | Taiwan xinyue rack |

| Vacuum pump | water-cooled vacuum pump 5.5KW |

| Lubrication system | Automatic lubrication |

| Vacuum cleaner | 3kw double cylinder vacuum cleaner |

CNC Wood Router Machine Advantage

1. With 8 or 12 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.

2.Vacuum table using high-density material with great suction strength, comfortably accommadating all sizes of work piece.

3. Control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

4.The frame adopts the gantry column structure, the machine parts are produced and assembled with extremely high precision to ensure the high performance and stability of the machine, excellent quality and tolerance.

Wood CNC Router Machine Applications

- Furniture Manufacturing: Wood CNC Router are widely used in the production of furniture. They can cut and shape components with precision, create intricate joinery, and add decorative details, resulting in high-quality and visually appealing furniture pieces.

- Cabinet Making: Wood CNC Router are essential in the production of cabinets. They can cut out cabinet parts, create precise joinery for assembly, and carve decorative elements, ensuring the production of functional and aesthetically pleasing cabinets.

- Sign Making: ATC Wood CNC Router are commonly used in the creation of signs. They can engrave letters, logos, and designs onto wooden signboards, allowing for personalized and professional-looking signage.

- Artistic Woodwork: Wood CNC Router have found their way into the world of artistic woodwork. Artists and sculptors use these machines to create intricate sculptures, relief carvings, and other artistic expressions in wood.

- Prototyping and Model Making: 4×8 Wood CNC Router are valuable tools for prototyping and modelmaking. They allow designers and engineers to quickly create accurate prototypes and models of their designs, enabling them to test and refine their ideas before moving on to production.

4×8 Wood CNC Router for Sale

- Precision and Accuracy: A Wood CNC Router eliminates the potential for human error, ensuring precise and accurate cuts every time. This level of precision is crucial for achieving seamless joinery, intricate designs, and a high-quality finish.

- Time Efficiency: With the ability to automate tasks and perform multiple operations simultaneously, a Wood CNC Router significantly reduces production time. This allows woodworkers to handle more projects and meet tight deadlines without compromising quality.

- Design Flexibility: Wood CNC Routers offer unparalleled design flexibility. They can bring intricate and complex designs to life, allowing woodworkers to explore their creativity and push the boundaries of traditional woodworking.

- Material Optimization: By optimizing the placement of cuts and minimizing waste, a Wood CNC Router helps maximize material utilization. This not only reduces costs but also contributes to a more sustainable approach to woodworking.

- Versatility: From cutting and shaping to engraving and carving, a Wood CNC Router offers versatility in woodworking. It can handle a wide range of wood species and thicknesses, making it an indispensable tool for both small-scale artisans and large-scale manufacturers.

Wood CNC Routers can be used by beginners in woodworking, although some learning curve is involved. It is essential to familiarize yourself with the software and machine operation. However, once you grasp the basics, these machines can greatly enhance your woodworking capabilities.

Yes, Wood CNC Routers can work with various types of wood, including hardwoods, softwoods, and even engineered wood products. The cutting speed and feed rate may vary depending on the wood species and its hardness, but the machine’s versatility allows for working with different materials.

While Wood CNC Routers offer many advantages, they cannot entirely replace traditional woodworking tools. Traditional tools such as hand planes, chisels, and saws still have their place in woodworking, especially when it comes to fine detailing and craftsmanship. Wood CNC Routers complement traditional tools and enhance the woodworking process.