In today’s fast-paced manufacturing industry, efficiency and precision are paramount. When it comes to drilling operations, CNC six-sided drilling machines have emerged as game-changers. These advanced machines offer unparalleled capabilities, enabling manufacturers to achieve higher productivity, accuracy, and cost-effectiveness. we will delve into the key features and benefits of CNC six-sided drilling machines, highlighting how they streamline drilling processes and elevate overall manufacturing operations.

CNC Six-Sided Drilling Machine

CNC six-sided drilling machines have revolutionized drilling operations in the manufacturing industry by combining automation, precision, and versatility. With their ability to drill on all six sides of a workpiece, these machines offer enhanced productivity, accuracy, and cost-effectiveness. By harnessing the power of CNC technology, manufacturers can streamline their drilling processes and achieve consistent, high-quality results. As the manufacturing landscape continues to evolve, investing in CNC six-sided drilling machines becomes an imperative step towards staying competitive and achieving operational excellence.

CNC six-sided drilling machine for panel furniture is accepted by panel furniture factories due to its advantages of fast production efficiency and high drilling precision, and its application is becoming more and more popular. Therefore, in the next few years in the industry, CNC six-sided drilling will become the development trend of panel furniture factories.

CNC Six-Sided Drilling Machine Advantages

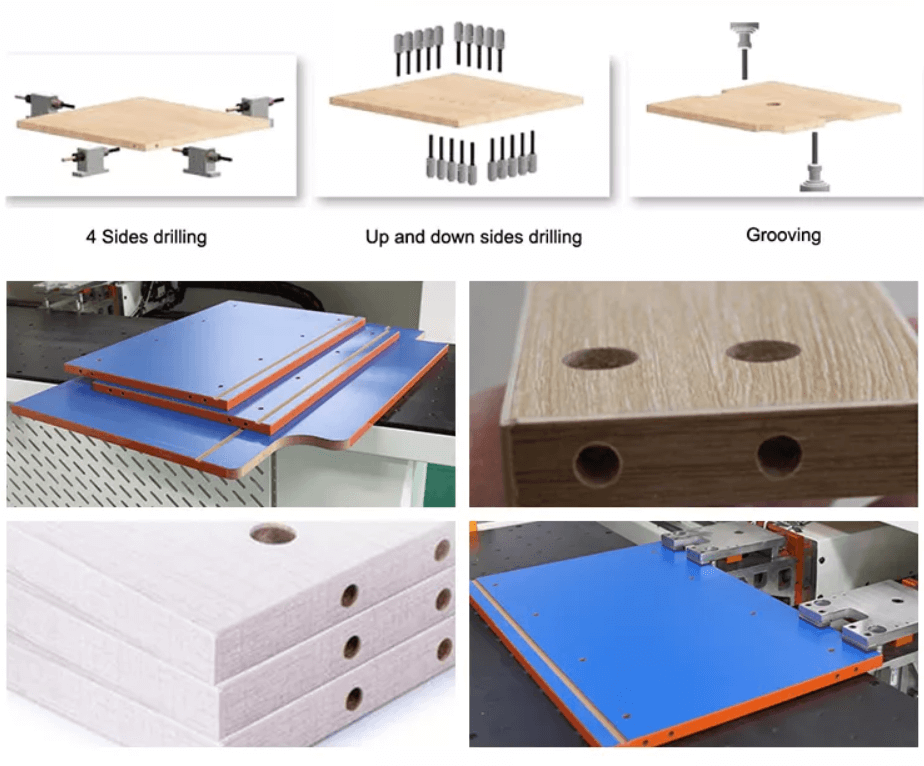

- Enhanced Productivity: Discuss how CNC six-sided drilling machines significantly boost productivity by automating drilling operations, eliminating the need for manual adjustments and reducing cycle times.

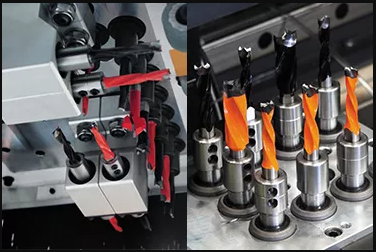

- Precision and Accuracy: Emphasize the exceptional precision and accuracy achieved by these machines, thanks to their advanced CNC control systems. Highlight the reduced risk of human error and the ability to consistently produce high-quality drilled holes.

- Versatility: Showcase the versatility of CNC six-sided drilling machines, which can handle a wide range of materials, including wood, plastic, composite, and metal, making them suitable for various industries.

- Complex Drilling Patterns: Explain how these machines excel in drilling complex patterns, such as holes, slots, countersinks, and counterbores, with consistent precision across multiple sides of a workpiece.

- Cost-effectiveness: Discuss the cost-saving benefits of CNC six-sided drilling machines, including reduced labor costs, minimized material waste, and improved overall operational efficiency.

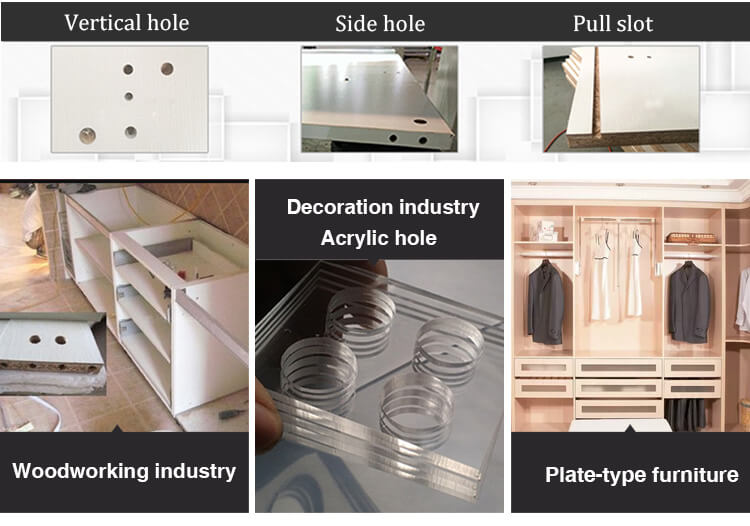

Six-Sided Drilling Machine Applications and Industries

- Furniture Manufacturing: Highlight how CNC six-sided drilling machine are extensively used in the furniture industry for drilling holes, dowel insertion, and hardware installation.

- Cabinetry and Joinery: Discuss how these machines streamline the production of cabinets, drawers, and other woodworking applications that require precise hole placement.

- Panel Processing: Explain how CNC six-sided drilling machines excel in drilling holes and cutouts in panels used for construction, interior design, and architectural applications.

- Automotive and Aerospace Industries: Showcase how these machines are employed in the automotive and aerospace sectors for drilling holes in metal components, including engine blocks, chassis, and aircraft parts.

- Electronics and PCB Manufacturing: Discuss the relevance of CNC six-sided drilling machines in the electronics industry for drilling holes in printed circuit boards (PCBs) and electronic components.

I am a supplier of woodworking panel furniture. Chinese CNC machines are affordable and high-quality,IGOLDENCNC is worth promoting.