Woodworking ATC (automatic tool changer) CNC router is a type of machine that is used to automate woodworking processes and increase efficiency. This type of router is equipped with an automatic tool changer, which allows for the rapid and precise changing of cutting tools during the routing process.

ATC Wood CNC Router

In the world of woodworking, precision, efficiency, and versatility are paramount. Enter the Automatic Tool Change (ATC) Wood CNC Router – a cutting-edge solution that revolutionizes woodworking processes. This comprehensive guide is your key to understanding the capabilities and benefits of ATC Wood CNC routers. From exploring the fundamentals of ATC technology to uncovering its diverse applications in woodworking, this guide equips you with the knowledge to optimize your woodworking operations and unleash your creativity.

It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

An Automatic Tool Change (ATC) Wood CNC Router is a sophisticated machining tool equipped with a tool magazine and a mechanism for automatically changing cutting tools during the machining process. Unlike manual tool changes, which require operator intervention and downtime, ATC routers streamline production by seamlessly switching between different tools as needed, enhancing efficiency and productivity.

Product Recommend

ATC CNC Router With Automatic Tool Changer

Step into a world of limitless possibilities with our state-of-the-art Woodworking ATC CNC Router with Tool Changer. Designed to revolutionize your woodworking experience, this cutting-edge machine combines precision, efficiency, and versatility to bring your creative visions to life like never before.

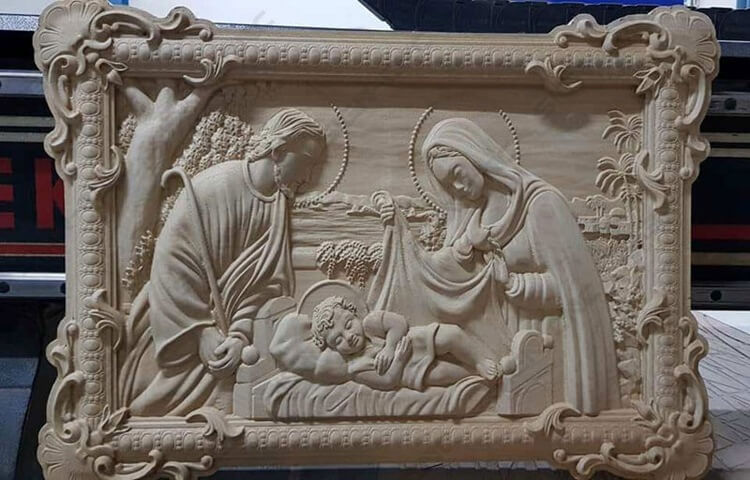

Unparalleled Precision

Experience woodworking at its finest with the Woodworking ATC CNC Router’s exceptional precision. Equipped with advanced technology and high-precision components, this machine ensures every intricate detail of your designs is flawlessly executed. From intricate carvings to intricate joinery, achieve perfection with ease.

Automatic Tool Changer

Say goodbye to time-consuming manual tool changes. Our Woodworking ATC CNC Router comes with an Automatic Tool Changer (ATC) that allows seamless and efficient transitions between different cutting, carving, and shaping tools. This feature not only saves you valuable time but also enables uninterrupted workflow, maximizing productivity.

Versatility Redefined

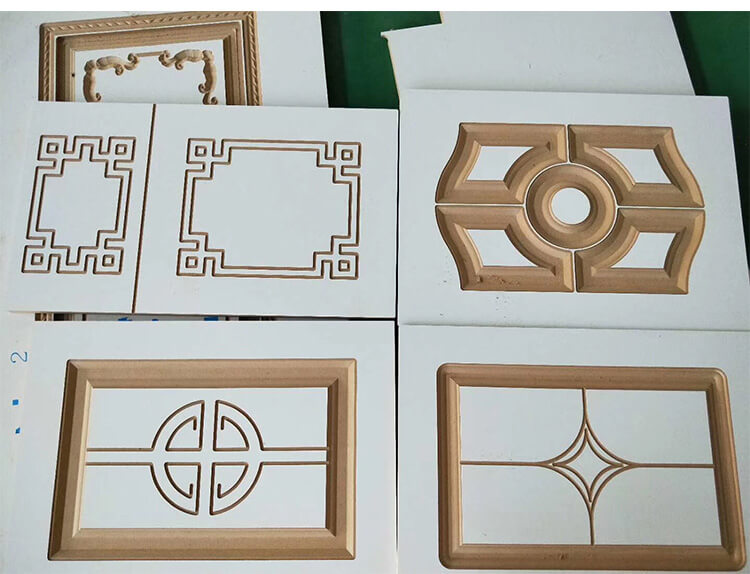

With the Woodworking ATC CNC Router’s tool-changing capabilities, you can explore a wide range of woodworking applications. Whether you’re crafting fine furniture, intricate cabinetry, decorative moldings, or even intricate wood engravings, this machine empowers you to push the boundaries of your creativity with ease.

Efficient Workflow

Boost your efficiency and optimize your workflow with the Woodworking ATC CNC Router. Its user-friendly interface and intuitive controls make operation effortless, allowing you to focus on unleashing your creativity. The machine’s rapid cutting speed, coupled with the automatic tool changer, ensures quick turnarounds and seamless production.

Enhanced Material Compatibility

The Woodworking ATC CNC Router is designed to accommodate a variety of materials, expanding your woodworking capabilities. From hardwoods to softwoods, plywood to MDF, this machine delivers exceptional results on various materials, enabling you to tackle diverse woodworking projects with confidence.

Reliable and Durable

Invest in a woodworking machine that stands the test of time. Our Woodworking ATC CNC Router is built with durability and reliability in mind. The robust construction and high-quality components ensure consistent performance, minimizing downtime and maximizing your return on investment.

Unmatched Customer Support:

We are committed to providing exceptional customer support throughout your woodworking journey. Our team of experts is available to assist you with any queries, technical support, or training needs, ensuring a smooth and seamless experience with our Woodworking ATC CNC Router.

Applications of ATC CNC Router Machine

The applications of ATC Wood CNC routers span a wide range of woodworking disciplines and industries. In furniture manufacturing, ATC routers excel at producing custom cabinetry, decorative panels, intricate carvings, and complex joinery with precision and efficiency.

Architectural woodworking benefits from ATC technology for producing intricate moldings, millwork, staircases, and decorative elements that enhance interior and exterior spaces. In the sign-making industry, ATC routers are indispensable for creating high-quality signage, lettering, logos, and 3D reliefs on a variety of materials, including wood, acrylic, and composite panels.

Artistic woodworking thrives with ATC routers, allowing craftsmen to explore creative designs, sculptures, and intricate patterns with ease and precision.

ATC Wood CNC routers offer a multitude of benefits for woodworking professionals and businesses. Firstly, they significantly reduce setup times and tool changeovers, maximizing uptime and throughput. This results in faster production cycles and shorter lead times, ultimately increasing profitability and competitiveness in the market.

Moreover, ATC routers enhance versatility by enabling the use of a wide range of cutting tools, including end mills, drills, saw blades, and specialty tools. This versatility allows woodworkers to tackle diverse projects with varying requirements, from intricate carving and engraving to precision cutting and shaping.

Furthermore, ATC technology improves accuracy and consistency by eliminating human error associated with manual tool changes. This ensures uniformity in finished products and minimizes waste, leading to higher quality and customer satisfaction.

Key Considerations when Choosing an ATC Wood CNC Router

Selecting the right ATC Wood CNC Router is vital to ensure optimal performance and productivity. Here are some essential factors to consider:

a. Machine Size and Work Area: Assess your workspace and determine the appropriate machine size and work area to accommodate your woodworking projects.

b. Spindle Power and Speed: Consider the type of wood materials and cutting requirements you will be working with. Choose a machine with an adequate spindle power and speed range to achieve desired results efficiently.

c. Tool Magazine Capacity: Evaluate the tool magazine capacity of the ATC Wood CNC Router. Ensure that it can accommodate the range and quantity of cutting tools you typically use for your projects.

d. Control System and Software: Look for a machine with a user-friendly control system and compatible software. The software should support your design needs and provide ease of use for programming and toolpath generation. e.Continuation:

e. Machine Durability and Build Quality: Consider the durability and build quality of the ATC Wood CNC Router. Look for machines constructed with robust materials and components that can withstand the demands of continuous use.

f. Support and Training: Ensure that the manufacturer or supplier provides comprehensive support and training for the machine. This will help you maximize the capabilities of the ATC Wood CNC Router and troubleshoot any issues efficiently.

g. Budget and Return on Investment (ROI): Determine your budget and evaluate the potential return on investment. While ATC Wood CNC Routers may require a significant initial investment, their efficiency and productivity gains can lead to long-term cost savings and improved profitability.

ATC Wood CNC Routers offer a multitude of benefits and applications for woodworkers and manufacturers in the woodworking industry. Their automatic tool changing capability, versatility, precision, and efficiency make them indispensable tools for creating intricate designs, producing custom woodworking projects, and streamlining production processes. By considering key factors when choosing a machine and implementing proper maintenance, woodworkers can harness the full potential of an ATC Wood CNC Router to achieve exceptional results and stay at the forefront of the woodworking industry.

I am a supplier of woodworking panel furniture. I purchased IGOLDEN’s automatic production efficiency. Chinese CNC machines are affordable and high-qualitytool change woodworking machine