CNC Router Wood Cutting Machine

A CNC router wood cutting machine is a computer-controlled cutting device specifically designed for woodworking applications. It utilizes a computer numerical control (CNC) system to accurately cut, carve, and shape wood materials.

An ATC (Automatic Tool Changer) CNC router for wood cutting is a machine that is designed to automatically change cutting tools during the machining process. This feature allows for greater efficiency and versatility in woodworking applications.

Routing and Cutting Capabilities

CNC router machines are versatile and can perform a variety of woodworking tasks, including cutting, carving, engraving, milling, drilling, and grooving. They can handle different types of wood, such as solid wood, plywood, MDF (Medium-Density Fiberboard), and more.

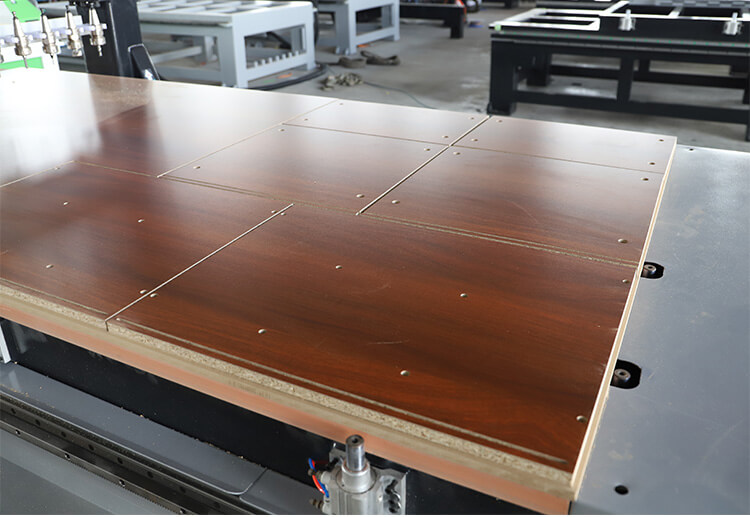

CNC router wood cutting machines come in various sizes, offering different cutting areas or bed sizes. The cutting area determines the maximum dimensions of the wood piece that can be processed. Consider the size requirements of your woodworking projects and choose a machine with an appropriate cutting area.

Spindle and Cutting Tools

CNC routers use a spindle to hold and rotate cutting tools, such as end mills, router bits, or drill bits. The spindle’s power and speed affect the machine’s cutting capabilities. Higher-powered spindles are suitable for cutting through thicker or tougher wood materials. The machine’s tool holder system and compatibility with different tool sizes are also important considerations.CNC routers use a spindle to hold and rotate cutting tools, such as end mills, router bits, or drill bits. The spindle’s power and speed affect the machine’s cutting capabilities. Higher-powered spindles are suitable for cutting through thicker or tougher wood materials. The machine’s tool holder system and compatibility with different tool sizes are also important considerations.

Automatic Tool Changer:The primary feature of an ATC CNC router is its ability to automatically change cutting tools. This allows for different tools to be used in a single job without manual intervention.

What Are CNC Router Wood Cutting Machine Used For?

These automatic machine tools are mostly used for woodworkers and carpenters to do woodworking in industrial manufacturing, small business, small shop, home business, home shop, school education. Besides, craftsman and hobbyists will also find a computer-controlled wood CNC machine useful.

Here are some of the fields where a CNC wood router will have access:

• Furniture Making: home furniture, art furniture, antique furniture, office furniture, cabinet making, door making, cabinet doors, interior doors, home doors, cupboard doors, table legs, sofa legs, wood spindles, corners, screens, headboards, composite gates, MDF projects, wood crafts, wood arts.

• Advertising.

• Die Making.

• Hollowing.

• Relief Carvings.

• Wood Cylinders.

• 3D Woodworking Projects.

• Sign Making.

• Custom Woodworking Plans.

What Are The Types Of CNC Router Wood Cutting Machines?

To categorize the types of an automatic woodworking machine, three possible categories can be made:

Types based on table sizes (work area): 2×3 table tops, 2×4 table tops, 4×4 table tops, 4×6 table tops, 4×8 table tops, 5×10 table tops, 6×12 table tops.

Types based on applications: Home types, Desktop types, 3D types, Hobby types, Commercial types, Industrial types.

Types based on axis: 5 axis, 4 axis, 4th axis (rotary axis), and 3 axis CNC wood routers.

When selecting a CNC router wood cutting machine, consider factors such as cutting capabilities, bed size, spindle power, precision, software compatibility, and safety features.

What Makes A Cnc Wood Router Machine Different From Others?

Although there are numerous excellent CNC routers offered today, the ideal machine for a woodworking application will certainly vary depending upon whether you’re a hobbyist aiming to do basic wood sculpting or if you’re doing some significant production work.

A wonderful CNC machine can make your woodworking production procedure smooth as well as allow you make points you would certainly discover challenging to do manually with any kind of power device.

Automatic Wood CNC Router Cutting & Engraving Machine

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

The most used CNC wood router tables include 2ft by 3ft, 2ft by 4ft, 4ft by 4ft, 4ft by 6ft, 4ft by 8ft, 5ft by 10ft, and 6ft by 12ft. A wood router is applied in most popular woodworking plans and projects such as cabinet making, door making, sign making, arts & crafts, furniture making, and home decorations. Whether you are a craft carpenter or a professional woodworker, you can easily find your next CNC router at IGOLDENCNC to automate your woodworking projects. Its user-friendliness, ease of use and multi-function make it easy for you to benefit and profit.

Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available. In addition, a variety of customization options and add-ons are also available to personalize your machine tools. Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.