Cabinet Production Line

How to build a cabinet with high quality and efficiency has always been what the cabinet makers are chasing for. Today’s market requires cabinet makers to use automated equipment and technology to gain a competitive advantage. And also meet the custom cabinet making requirements of customers. The advent of CNC machinery has provided the tools, support and resources that exceed manual machines to build a cabinet. It has made cabinet making much more efficient.

Panel Furniture Production Line Video

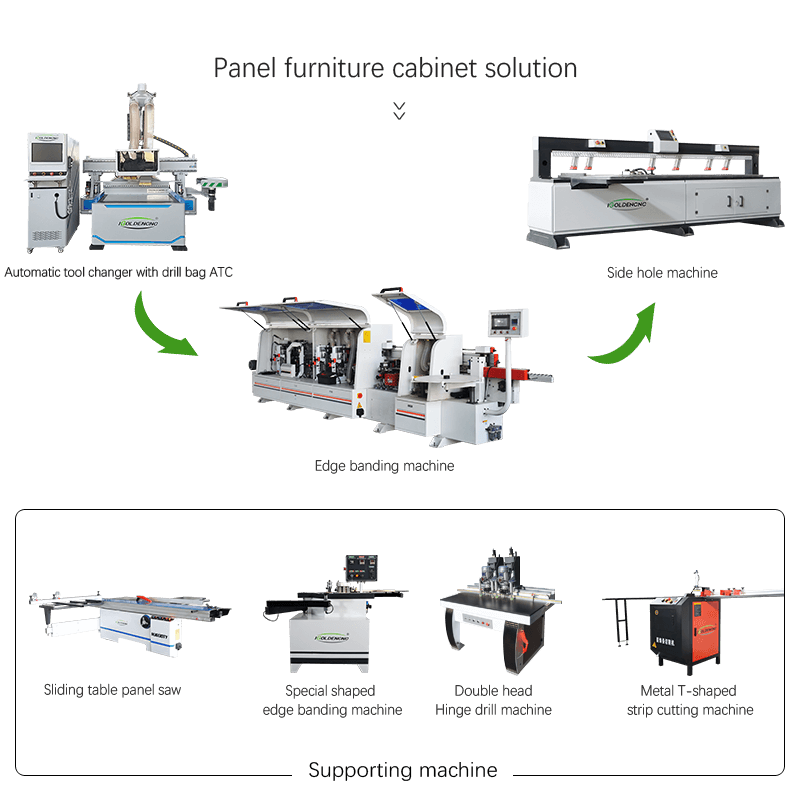

Using CNC machines to build cabinets can effectively control costs and improve machining efficiency. So I recommend using a cabinet production line to build a cabinet. This production line, with simple operation but multiple functions, is dedicated to the production of cabinet body. It consists of three machining units, namely nesting unit, edge banding unit and drilling unit. This production line applies to the machining of kitchen cabinets, wardrobes, cupboards, shelves and other cabinet bodies.

Nesting unit mainly includes a four-process nesting CNC machine. It can complete the cutting, grooving and drilling processes in the course to build a cabinet.

Edge banding unit consists of an automatic edge banding machine and a folding arm curved edge banding machine. This unit is used to band straight and curved edges in the process to build a cabinet.

Drilling unit mainly include a CNC side drilling machine for drilling side holes on panels.

Woodworking CNC Router Application:

Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

Contact Us Today to Get Price!

Reviews