Automated Linear ATC CNC Router Woodworking Machine

ATC CNC router is one of the most classic and popular CNC among the tool change engraving machines. It adopts the linear tool change mode with a fast tool change speed, and the tool change can be completed within a few seconds without any people’s operation, which greatly improves productivity.

Linear ATC CNC router woodworking machines are widely used in industries such as furniture manufacturing, cabinetry, woodworking shops, and architectural woodworking. They offer efficient and precise machining capabilities.

ATC CNC Router Video

ATC CNC Router For Wood Parameter

| Model | iGW-ATC-2131 |

| Working area | 2100*3100*250mm |

| Spindle | HQD 9.0kw Air Cooling ATC Spindle |

| Gantry | Steel Structure |

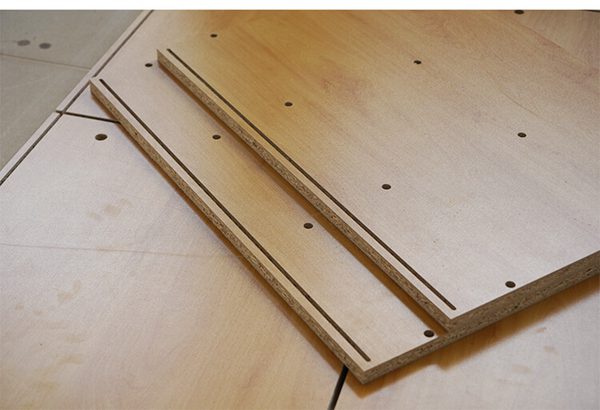

| Worktable | PVC vacuum suction can suck and clamp the table |

| Guide Rails | Taiwan HIWIN |

| Driver | Dongling Servo Drive and Servo Motor |

| Reducer | Japan SHIMPO |

| Frequency Converter | Fuling / Delta |

| Vacuum pump | 7.5KW air cooling vacuum pump |

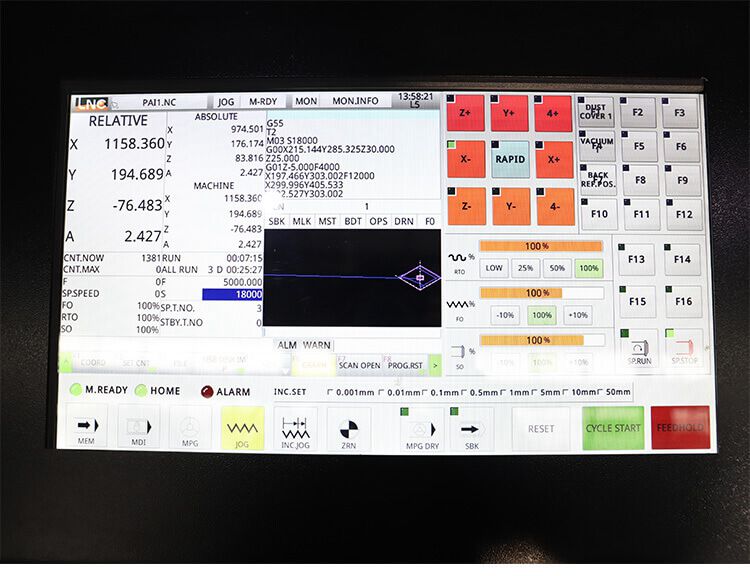

| Control System | Taiwan LNC |

| Dust collection system | 3KW Double bucket vacuum cleaner |

| Working Voltage | 380V/50Hz |

If you need more detailed information, please inform us as soon as possible.

Wood ATC CNC Router Features

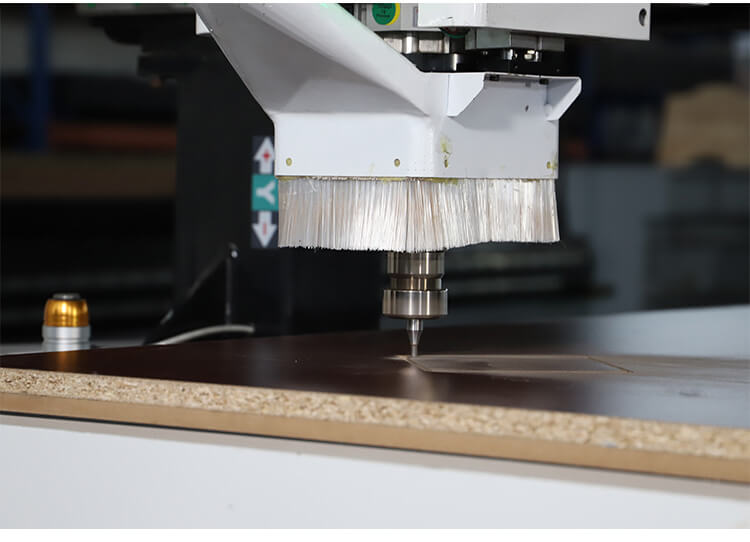

ATC wood CNC router machine is a type of heavy-duty and multi-purpose CNC woodworking machine with automatic tool changer for carving, milling, drilling, grooving, and cutting from igoldencnc. It has the industrial features of high precision, high speed, constant torque, low runout, strong stability and long life.

In-line tool change tool magazine

With 8 or 12 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

Controller System

Design: The interface adopts the international standard G code command, which is compatible with domestic and foreign engraving, and the operation is simple. High quality, reasonable price and economical.

High-speed driver and stepper motor can improve work efficiency

Italy HSD air cooling spindle and the working speed can reach up to 24000RPM.

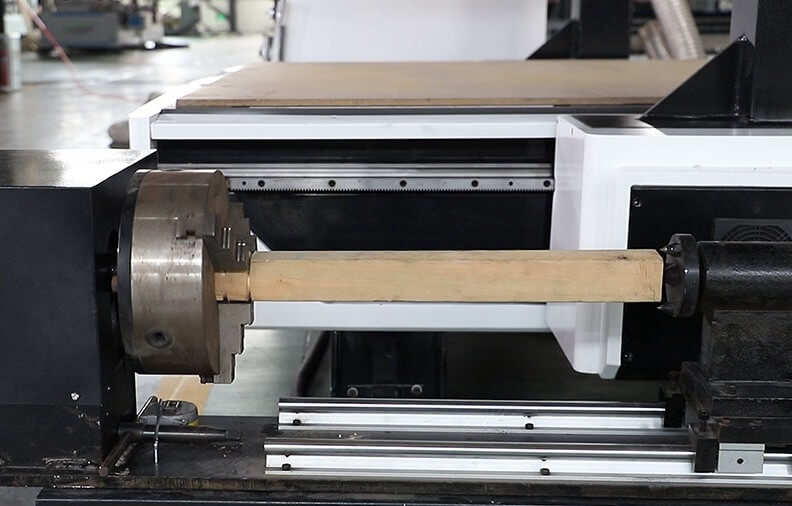

Table rotation axis (optional)Rotary Axis (The 4th Axis of CNC Router / 4 Axis CNC Router)

We can build the Rotary Axis CNC Router. At the same time, the rotary shaft device can also be added to the standard CNC Router to realize the cylindrical engraving working. Thus, round material and flat material can be processed in one CNC Router. It will save a lot of time and improve high efficiency.

Application

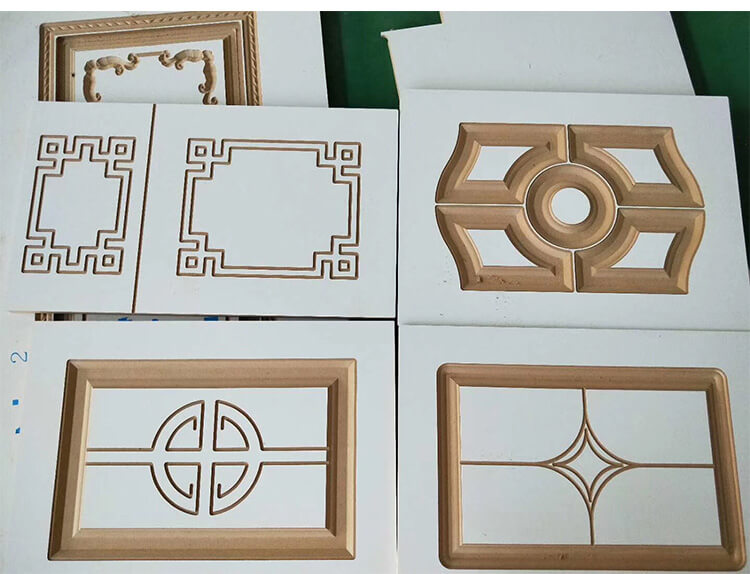

Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

Contact Us Today to Get Price!

- Automatic Tool Change: The Linear ATC system enables the machine to automatically change cutting tools without manual intervention. This eliminates the need for manual tool changes, saving time and improving productivity.

- Versatile Cutting Capabilities: The machine can accommodate a variety of cutting tools, including router bits, drills, and engraving tools. This versatility allows for a wide range of woodworking operations, such as cutting, carving, drilling, grooving, and engraving.

- Efficient Workflow: With automatic tool changes, the machine can perform multiple operations without requiring operator intervention. This results in a more streamlined workflow, reducing downtime and maximizing productivity.

- High Precision and Accuracy: The CNC control system ensures precise and accurate cutting, carving, and machining operations. The linear guide rails and ball screws provide smooth and stable movement, maintaining consistent precision throughout the machining process.

- Customization and Flexibility: The machine can be programmed to execute complex designs and intricate patterns, offering customization options for various woodworking projects. It allows for the production of customized furniture, cabinetry, doors, moldings, and other woodworking components.

- Time and Cost Savings: The automatic tool change capability reduces the manual labor required for tool changes, leading to time savings and increased efficiency. Additionally, the machine’s high precision and accuracy minimize material waste, optimizing material utilization and reducing costs.

- User-Friendly Interface: CNC routers typically feature user-friendly interfaces and software that allow operators to easily program and control the machine. This simplifies operation and reduces the learning curve for new users.

- Scalability and Production Volume: Linear ATC CNC router woodworking machines are available in various sizes and configurations, allowing for scalability based on production requirements. They can handle small-scale projects as well as large-scale production volumes.

1).ATC CNC router generally adopts high-power CNC Router Tool Changer spindle, and the most commonly used ones are 9kw and 12KW spindle. The high-power spindle has fast startup and high torque, which can give full play to the advantages of high speed and high efficiency of high-power tool change spindle.

2).ATC CNC router generally adopts high torque servo motor made in Japan and is equipped with reducer with high reduction ratio. This makes CNC router with tool changer machining center have the advantages of low noise, high speed and high positioning accuracy.

3).Equipped with a unique tool changing device, the required tools can be changed at will, and the special tool setting table can accurately compensate the tool length error. The tool change time of the cnc automatic tool changer is only a few seconds. The standard tool magazine comes with 8 tools, which can customize the tool magazine with larger capacity.

ATC machines can be of two main types based on the magazine shape. The carousel type and linear type are the two types of ATC available.

3D reliefs, signs, furniture, cabinets, etc.