CNC milling machine is mainly for cutting, carving, and milling various metal, plastic and wood materials. It can process planes, grooves, split parts, spiral surfaces, and curved surfaces, and also be used to process surfaces and inner holes of a rotary body. The machine falls in many types, such as elevating table, gantry, single-column, worktable non-lifting, and also the type for instrument, tool, and other purposes.

5 axis CNC router machine is a large format industrial CNC machining center, The CNC machine was designed for high precision machining and adopts a massive oversized steel frame, the rigidity of the machine is paramount to achieve high quality parts and eliminating any vibration at the tool tip.Large gantry 5 axis CNC machine is heavy duty industrial CNC router machine used for trimming formed parts, aerospace, molds, patterns, composites, automotive, large envelope parts, other 3D surface milling and 3D shape cutting projects.

5 Axis CNC Router Milling Machine Features

- The T slot & vacuum table with 2 zones has stronger adsorption capacity and is easier to fix the material.

- The metal sheet cover on the Z axis is both beautiful and dustproof.

- 12-tool carousel magazine can automatically change tools to realize more complex works.

- The 12kw water cooling spindle can rotate 360° for fast 3d engraving.

- All accessories are from international first-line brands, ensuring the processing accuracy and quality.

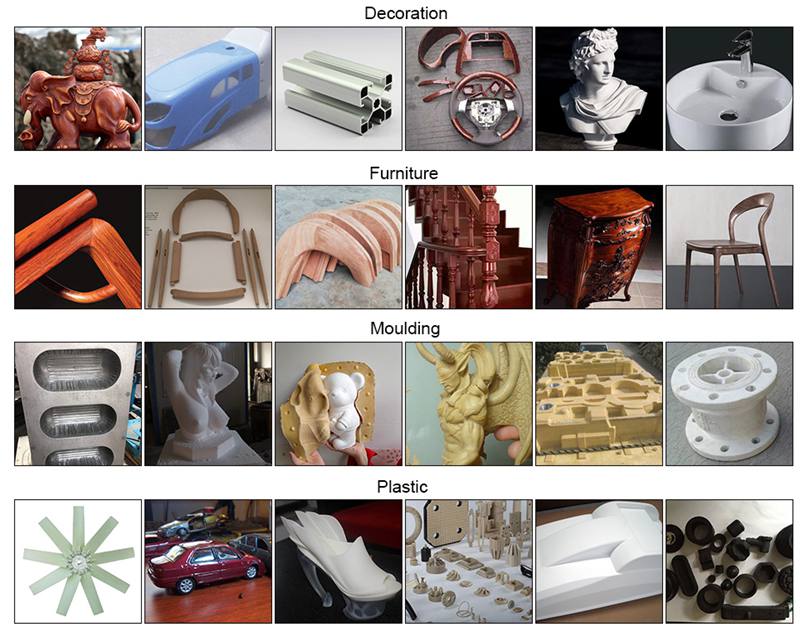

5 Axis CNC Router Milling Machine Applications

Mold Industry: Large metalloid moulds, automotive foam mold, wooden ship model, wooden model aviation, rail wooden mold and wooden mold train.

Instrument Industry: 3D surface engraving and 3D shape cutting of large-scale instruments.

Furniture Industry: deally suitable for processing cabinet door, wooden door, solid wood furniture, stereo box, computer desk, game cabinets, etc.

Decoration Industry: acrylic, PVC, density board, stone, organic glass, soft metals like aluminum and copper, etc.

Five-axis CNC machines have been an indispensable automatic tool for machining continuous, smooth, and complex surfaces in recent years. Once you encounter unsolvable problems in designing and manufacturing complex curved surfaces, you will turn into five-axis machining technology for help.

Five-axis linkage is the most difficult and widely used in CNC technology. It integrates computer control, high-performance servo drive and precision machining technology, and is applied to efficient, precise and automatic machining of complex curved surfaces. It is a symbol of the automation technology level of a country’s manufacturing equipment. Due to its special status, it has an important influence on aviation, aerospace, and military industries.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.