1325 ATC Wood CNC Router Machine

Linear ATC CNC wood router with LNC control system is designed for cabinet making, door making, furniture making, home decorations, wood crafts, musical instruments, windows, and tables. Now the best linear ATC wood CNC machine for sale at affordable price.

4 axis CNC router machine is based on the ordinary 3 axis CNC machine, adding the fourth axis (rotary axis).

Linear ATC CNC router Parameter

| Working area | 1300*1300*250mm |

| Spindle | 9KW air-cooled tool change spindle |

| Control system | LNC |

| Reducer | SHIMPO |

| Inverter | Fu Ling |

| Table | Vacuum suction can suck and clamp the countertop |

| Vacuum pump | 5.5KW air-cooled vacuum pump |

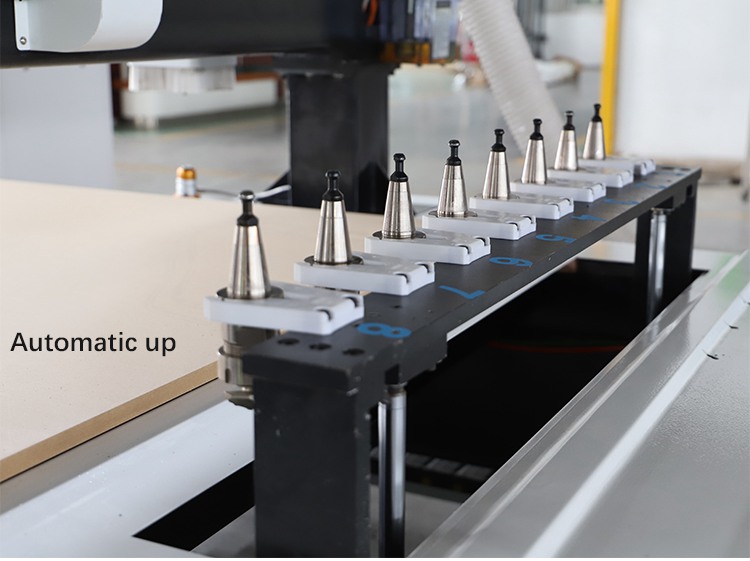

| Tool change | 8 tools in the back row |

| Rail | Taiwan HIWIN |

| Voltage | 380V 50HZ |

Linear ATC CNC Nesting Machine for Furniture Market

Linear ATC CNC Nesting Machine suitable for solid wave board process, door of cabinet, wooden door, artistic wooden door, no-paint door, avoid wind, process of the artistic window, shoes cleaning machine, the cabinet of the playing machine and the board, mahjong table, computer table.

This Linear ATC CNC Nesting Machine adopts double-station processing, which greatly improve the efficiency. Two working platform can realize automatic loading and unloading operation, no idle time, and it can increase capacity by 30%-40%.

- 1. CNC router table can meet any processing in non-metal/soft-metal materials, such as solid wood, MDF, acrylic, plastic, aluminum, copper, brass, etc.;

- 2. Small size takes little space, but powerful at carving 3D surface, cylinder object, and automatic woodworking;

- 3. CNC kit of the rotary device is essential for the processing of cylindrical workpieces;

- 4. CNC kits of ATC spindle, manages and picks up the right bits during woodworking, no need any manual assistant, saves time and labor, automatic your woodworking;

- 5. LNC Controller brings this CNC machine high stability and simple and convenient operation;

- 6. Brand CNC router kit ensures the CNC machine durable and longer life;

Application

The 4 axis ATC CNC router here refers to the ATC CNC router with a rotating spindle, which can swing 180° from left to right. The working path of the 4 axis ATC CNC router includes X, Y, Z and A axis. So it is also suitable for cutting and engraving 3D workpieces, such as foam molds, wood and stone sculpture and statues except for the basic applications. In addition, it can also drill side holes or make side grooves or slots on the side of wood panels. The 4 axis ATC CNC router has an extensive use in sculpture and statue making, mold, furniture, decoration, craft, advertising and other fields.

Linear ATC CNC Router VS Circle ATC CNC Router

ATC CNC router is the first choice for enterprises with large production volume. Compared with the traditional manual tool change production method, this type of wood CNC machine has an independent tool magazine with different tool bits. It can automatically change the required tools by computer program control without stopping work during processing. And this CNC wood router can complete a series of cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing needs. Therefore, both the processing quality and processing efficiency have been greatly improved.

According to the different tool changing methods, the ATC CNC engraving machine can be subdivided into linear ATC CNC and Circle ATC CNC machines. Then we are talking about the linear ATC CNC Machine. This type machine uses a straight-line tool change device, and the tool change device can be installed in different positions according to the specific needs of the user. Firstly, the in-line tool magazine can be placed behind the bed. This conventional in-line tool changer engraving machine is cost-effective and can meet a variety of processing requirements for complex work pieces without high procurement costs. Secondly, the in-line tool magazine can also be placed under the gantry. This type of linear engraving machine does not need to go to the back of the bed to change tools, so the tool change speed is faster and the wear on the guide rail can be reduced, and the service life of the machine is relatively longer. It is worth mentioning that the number of tools in the in-line tool magazine can be customized according to the specific processing needs of the user.

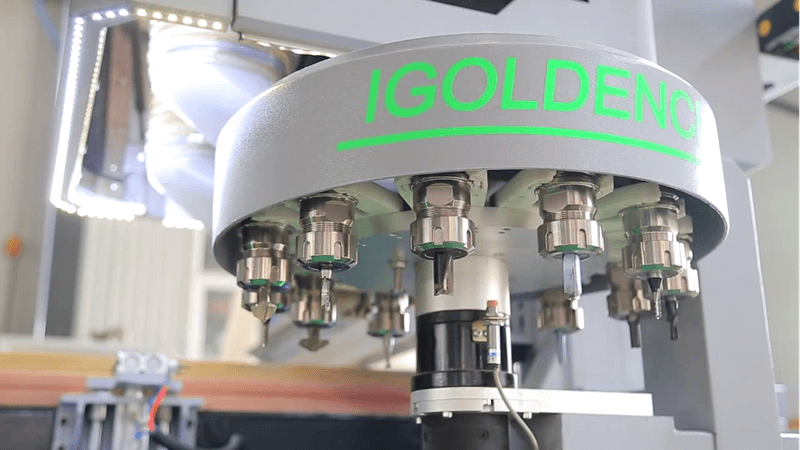

Next we are talking about the carousel ATC CNC Machine. This type machine is also one of the most selected by users. The position of the Circle magazine can also be selected according to user needs. On the one hand, the Circle magazine can be placed next to the spindle. The biggest advantage of this type machine is the fast tool change. However, the number of tool bits should be guaranteed to be within 20 tools. If the number of tool exceeds 20, the weight of the cutter head will increase, which will affect the bearing capacity of the Z axis and the gantry, especially the Z axis screw and the guide rail slider. And all these will affect machining accuracy. On the other hand, the disc magazine can be placed on the side of the gantry. This type of automatic tool changer engraving machine is not limited by the number of tools and has better stability. It also guarantees the processing accuracy of the machine and ensures that the ATC CNC router machine will be used for a long time, and processing accuracy is not affected.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.