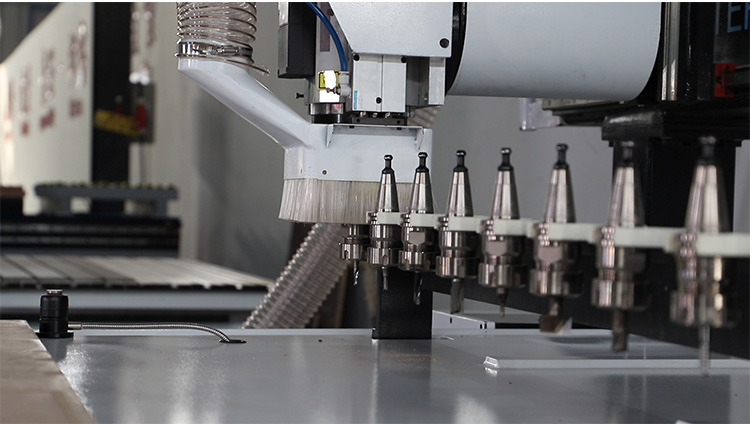

The 2040 ATC CNC Router is a state-of-the-art machine equipped with an Automatic Tool Changer (ATC). This feature allows the machine to switch between different tools automatically during the machining process, significantly enhancing productivity and reducing downtime. The “2040” in its name typically refers to the machine’s working area dimensions, which are 2000mm x 4000mm.

2040 ATC CNC Router

The 4 Axis 2040 ATC (Automatic Tool Changer) CNC Router is a versatile machine used for a variety of applications, including woodworking, metalworking, and manufacturing. This feature enables the machine to automatically change tools during the machining process, which improves efficiency and reduces manual intervention.

4-Axis Control: Allows for more complex and intricate designs, as it can move in four directions (X, Y, Z, and A axis). The A-axis typically allows for rotational movement around one of the other axes.

ATC CNC Router with Tool Changer is a type of CNC machine that is equipped with an Automatic Tool Changer (ATC) function. This feature allows the machine to automatically switch between different cutting tools without the need for manual intervention.

Applications of the ATC CNC Router

Woodworking

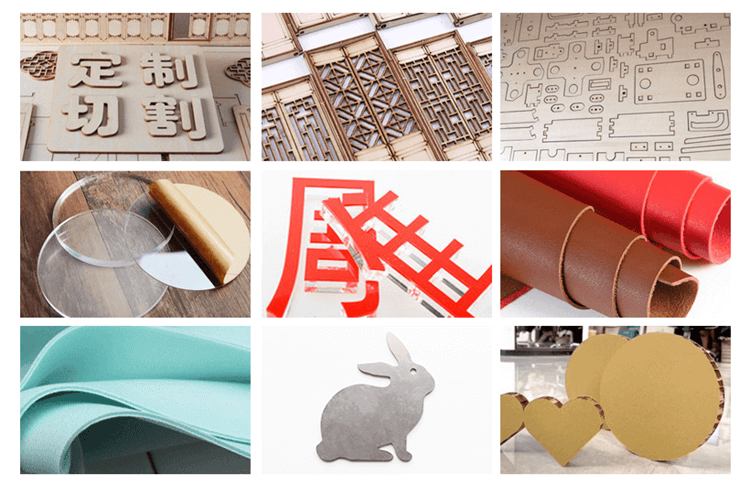

In the woodworking industry, the ATC CNC Router with Tool Changer is used to create intricate designs, furniture, cabinetry, and decorative elements. Its large working area and precision make it ideal for handling large sheets of wood and producing high-quality products.

Signage

In the signage industry, the ATC CNC Router is used to create custom signs, letters, and logos. Its precision and versatility allow for the production of detailed and eye-catching signage that meets clients’ specifications.

Furniture Making

The 2040 ATC CNC Router is a valuable tool for furniture makers. It can cut and shape various materials, including wood, MDF, and plywood, to create custom furniture pieces. The machine’s precision ensures that each piece fits together perfectly, resulting in high-quality furniture.

Features and Benefits of an Atc CNC Router with Tool Changer:

- Efficiency and Productivity: The automatic tool changer enables quick and seamless tool changes, reducing downtime and increasing overall efficiency and productivity.

- Versatility: With the ability to switch between different cutting tools, an ATC CNC Router can handle a wide range of CNC routing tasks, making it suitable for various applications such as carving, cutting, hollowing, grooving, punching, and milling.

- Large Working Area: With a working area of 2000mm x 4000mm, this router can handle large sheets of material, making it ideal for a variety of applications.

- Precision and Accuracy: The ATC CNC Router is designed to provide high precision and accuracy in cutting and carving operations. It is equipped with advanced control systems and servo motors to ensure precise tool positioning and movement.

- Time and Cost Savings: By automating the tool changing process, an ATC CNC Router eliminates the need for manual tool changes, saving time and reducing labor costs. It also minimizes the risk of human error during tool changes.

- Increased Flexibility: The ability to switch between different cutting tools allows for greater flexibility in design and production. It enables the machine to handle complex and intricate designs with ease.

Maintenance and Care ATC CNC Router

ATC CNC Router can handle a wide range of materials, including wood, metal, plastic, and composite materials. Its versatility makes it suitable for various applications across different industries.

Regular Cleaning

To ensure the longevity and optimal performance of your ATC CNC Router, regular cleaning is essential. Dust and debris can accumulate on the machine’s components, affecting its efficiency.

Tool Maintenance

The tools and bits used in the machine should be regularly inspected and maintained. Sharpening or replacing worn-out tools can prevent damage to the machine and ensure clean, precise cuts.

Software Updates

For machines with automated features, keeping the software up to date is important. Manufacturers often release updates that improve performance and add new features.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.