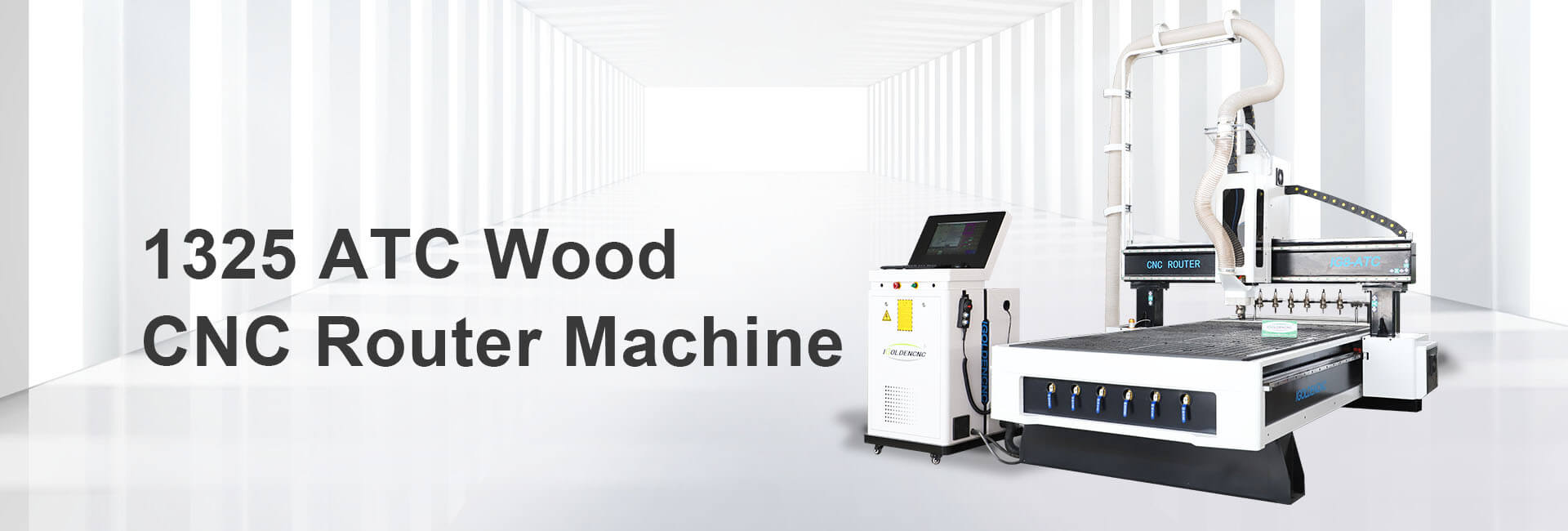

1325 ATC Wood CNC Router Machine

This 1325 ATC CNC router is one of the most classic and popular CNC among the tool change engraving machines. It adopts the linear tool change mode with a fast tool change speed, and the tool change can be completed within a few seconds without any people’s operation, which greatly improves productivity.Linear ATC CNC wood router with LNC control system is designed for cabinet making, door making, furniture making, home decorations, wood crafts, musical instruments, windows, and tables. Now the best linear ATC wood CNC machine for sale at affordable price.

ATC CNC Router Video

ATC CNC Router Machine Parameter

| Working area | 1300*2500*200mm |

| Spindle | ATC 9KW air cooling spindle |

| Inverter | Fuling |

| Motor | Dorna servo motor and driver 1500W and shimpo Reducer |

| Driver | Dorna servo motor and driver 1500W |

| Control System | LNC |

| Table | Vacuum and T slot table with 5.5kw cooling pump |

| Oil lubrication | Automatic lubrication |

| Limit | Omron limit |

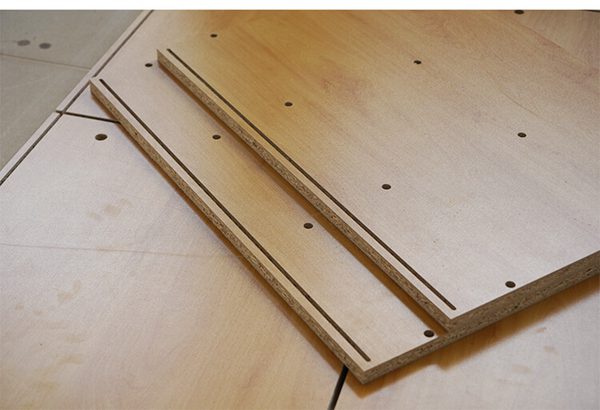

| Transmission | XY axis helical rack Z axis Taiwan ball screw |

| Rail | X,Y,Z axis Taiwan HIWIN Square guide rail |

| Screw | Z axis TBI 3210 ball screw |

| Bed | Thick steel welded big square tube |

| Gangry | Strong frame |

| Pillars | Steel pillar |

| Cabinet | Independent cabinet |

| Voltage | 3 phase/380V |

| Dust collector | Double bags 3.0kw |

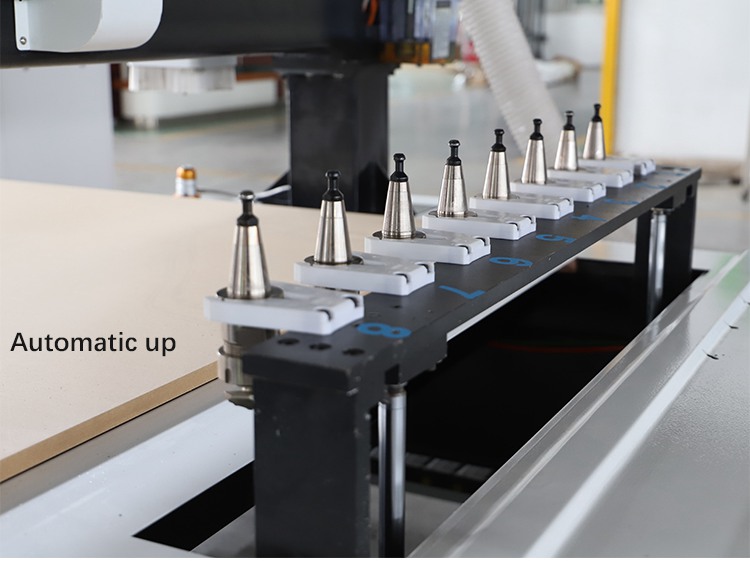

| Tool library | Automatic up and down |

We offer customized services according to your requests such as the working area and specifications.

4×8 ATC CNC Router Machine Features

1. Sturdy steel structure, good rigidity, no deformation, and durable.

2. High precision, suitable for handicraft advertising industry.

3. Design: The interface adopts the international standard G code command, which is compatible with domestic and foreign engraving, and the operation is simple. High quality, reasonable price and economical.

4. High-speed driver and stepper motor can improve work efficiency.

Tool Changer UP

Tool magazine: 8 slots linear tool changer kit, tool changes to be performed quickly.8 pcs linear auto tool changer follow with spindle, it can catch 8pcs different CNC bits for different work, no need to change bits by hand, the tool changing speed just 5s.

Tool Changer DOWN

With 8 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.

NK280 control system

Control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

Italy HSD air cooling spindle and the working speed can reach up to 24000RPM.

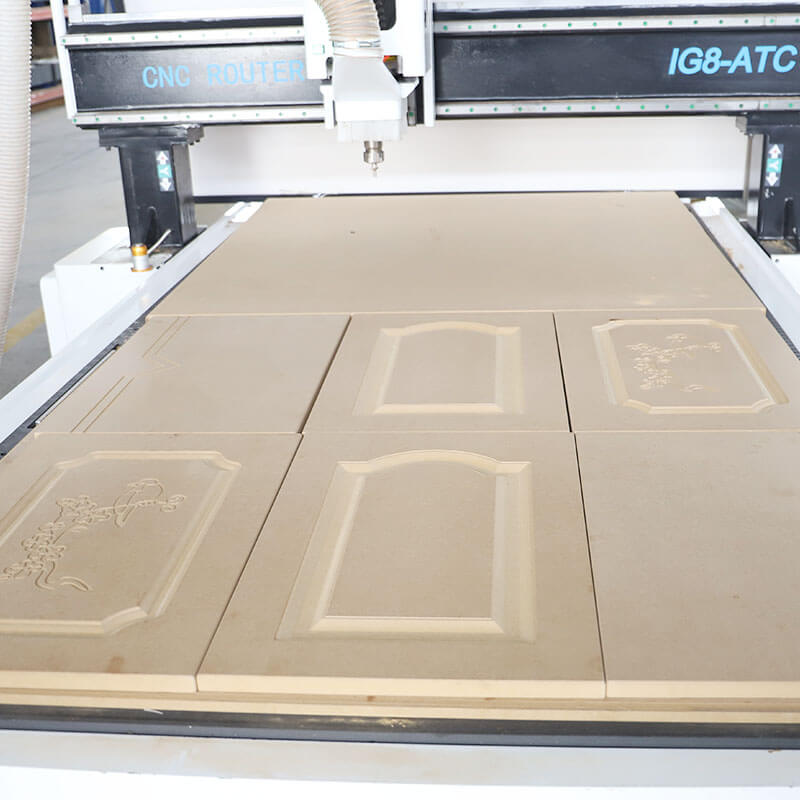

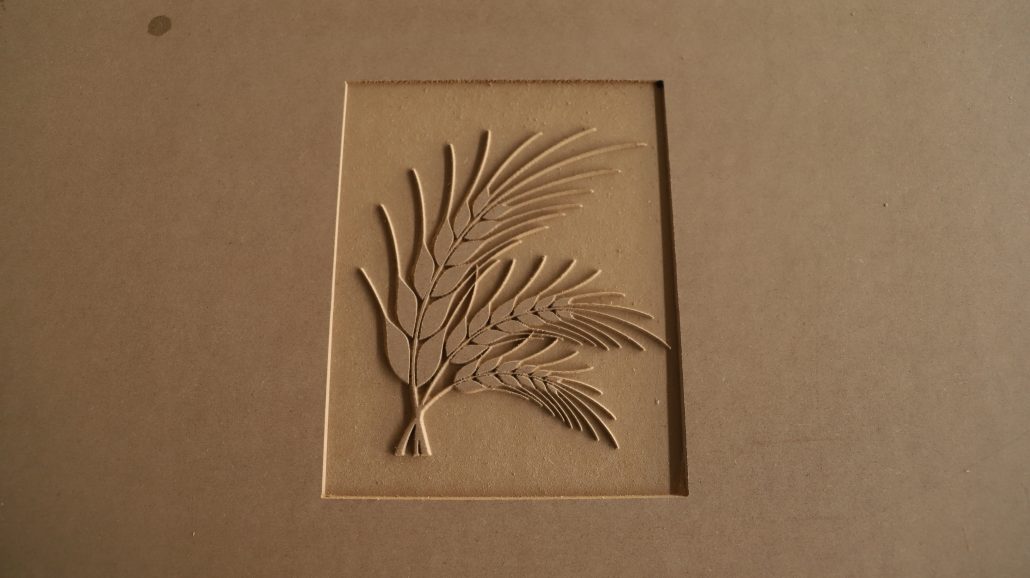

1325 ATC CNC Router Machine Application

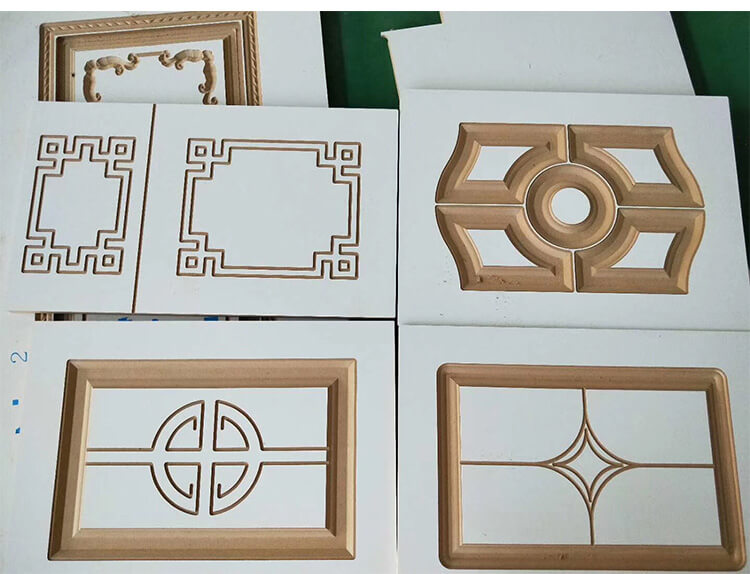

Wooden furniture industry:ATC CNC Router with Rotary Device is a combination of 3 axis CNC, 4 axis CNC, ATC CNC and rotary device for wood carving and engraving. The automatic tool change function greatly saves manual tool changing time and increases work efficiency. So fewer operator will be needed to watch and assist the CNC machine’s work.The 4 axis ATC CNC router has an extensive use in sculpture and statue making, mold, furniture, decoration, craft, advertising and other fields.

Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

Contact Us Today to Get Price!

ATC CNC router is a type of smart CNC machine with automatic tool changer spindle kit. ATC is refer to Automatic Tool Changer, the ATC spindle usually carries a tool magazine of 6 cutters or 8 cutters or 10 cutters or 12 cutters. The CNC router tools can automatically change according to the working requirements when the CNC router works, no need of manual operation, with good starting performance and large torque, it can give full play to the advantages of the machine’s high speed and higher efficiency. It adopts high-torque servo motor made in Japan, which has the advantages of low noise, high speed and high positioning accuracy.

Equipped with a unique tool-changing mechanism, you can exchange the required tools at will, and the dedicated tool setting table can accurately compensate the tool length error. The tool change time only takes a few seconds, which will improve the working efficiency greatly. There are two most common types ATC CNC machines, which includes linear type automatic tool changers and rotary type automatic tool changers. The best ATC CNC router machine adopts a rotary 4th axis for 3D cutting and carving.

1. Standard plywood case, its compressive strength and bearing quality is better.

2. The board area is bit, the soil structure is good, it is better in leakproofness and waterproof.

3. When importing, the plywood case is with fumigation-free, the procedure is simple.

The spindle motor power and speed options for 1325 ATC CNC router machines can vary depending on the specific machine model, manufacturer, and intended application. Here are some common power and speed options you may come across:

- Spindle Motor Power: The power of the spindle motor is typically measured in kilowatts (kW) and can range from 3 kW to 9 kW or even higher. The power requirement depends on the type of material being machined, the cutting depth, and the desired cutting speed. Higher power spindle motors are generally capable of handling more demanding cutting tasks and harder materials.

- Spindle Speed Range: The spindle speed refers to the rotational speed of the spindle motor and is usually measured in revolutions per minute (RPM). The speed range can vary significantly, but common options for 1325 ATC CNC router machines typically fall within the range of 6,000 RPM to 24,000 RPM. Lower speeds are suitable for cutting softer materials, while higher speeds are used for faster cutting and finer detail work.

It’s important to consider the specific requirements of your woodworking projects when selecting the spindle motor power and speed for your 1325 ATC CNC router machine. Harder materials or deeper cuts may require higher power and lower speeds to maintain optimal cutting performance and quality. On the other hand, softer materials or finer detail work may benefit from higher spindle speeds.

When purchasing a 1325 ATC CNC router machine, it’s recommended to consult with the manufacturer or supplier to ensure that the machine’s spindle motor power and speed options align with your specific application needs. They can provide guidance based on their expertise and knowledge of the machine’s capabilities.