Automatic Tool Change CNC router machine simply to say ATC CNC Router. An Automatic tool changer or ATC is used in computerized numerical control (CNC) machine tools to improve the production and tool carrying capacity of the machine. ATC changes the tool very quickly, reducing the non-productive time., it is used to improve the capacity of the machine to work with a number of tools. It is also used to change worn out or broken tools. It is one more step towards complete automation.It adopts an automatic tool changer spindle with an auto tool magazine with 8 or 10 cutters, the tools can automatically change to fit different working processes. The automatic tool magazine can be a carousel type of linear type.

ATC Wood Engraver with Drilling Holes

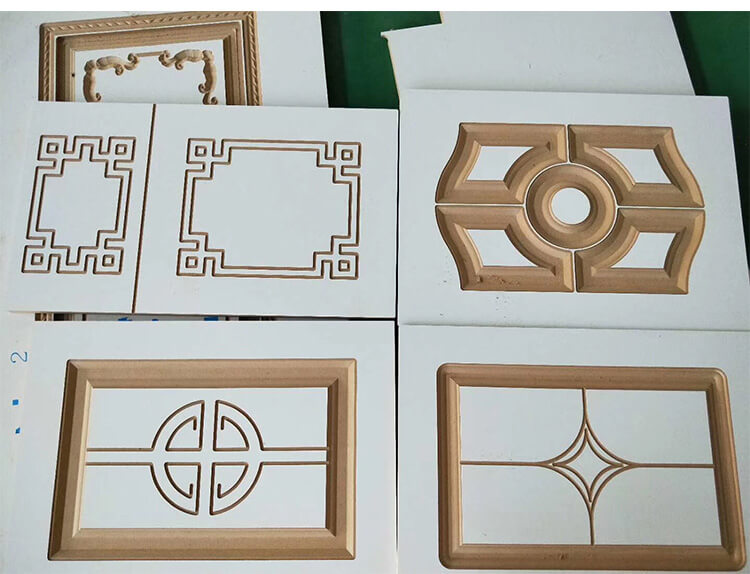

An ATC CNC Router automatically changes cutters between tool paths and eliminates the need for the CNC operator to change and zero tools individually. The ATC Wood Router allows customers to do the full job, even when different tooling is required to make different types of cuts – like cabinets and furniture – or where different bits are needed for roughing and finishing passes – like signs and complex 3D carvings. With an ATC can perform operations normally done on other pieces of equipment, eliminating the need for additional machines in the shop. Save CNC Router Machine cost and labor cost from the very beginning. ATC CNC Wood Router is suitable for wood, MDF, plywood, PVC, Acyclic, Aluminum engraving, cutting and milling.

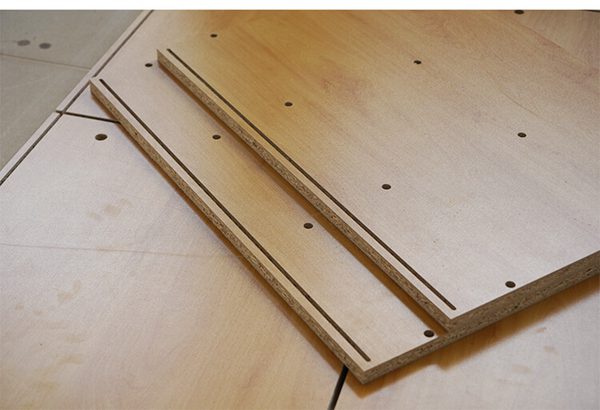

What’s the boring head and why we choose it? A boring head also can be stated drilling block. There are many types of drilling blocks, 9 pcs vertical heads, 4 horizontal drilling heads and 9 vertical heads. Normally, We install 9 heads drilling block on our ATC Woodworking Wood Engraving cutting CNC ROUTER.

If you buy CNC Wood Router for wood panel and normal nested based cabinet parts process and you have mass production volume, a drilling block worth you to buy.

The drilling block on the Wood Router can save time and reduce material handling requirements. It is one cost-effective choice. Our CNC Router machine has a 9 head vertical drilling block and sometimes I wish it was double. The drilling operations take longer than the cutting. For reference, we nest our drawer parts (3/4 mel) with the case parts and we’re drilling for dowels. Also, we’re drilling for confirmations and 20mm drawer front adjusters. That’s 4 drill sizes, so we go with 6-5mm, 1 each 7, 8 and 20mm drills.

An auto tool changer (ATC) is a feature commonly found on CNC routers that allows for automatic changing of cutting tools during machining operations. It eliminates the need for manual tool changes, thereby reducing downtime and increasing productivity.

A boring head is a specialized cutting tool used for enlarging or refining existing holes in materials. It is commonly used in woodworking, metalworking, and other machining applications. The boring head typically consists of an adjustable cutting tool holder that can accommodate various sizes of boring bars or drill bits.

When combined, an auto tool changer and a boring head on a CNC router can provide efficient and versatile machining capabilities. The ATC enables the router to automatically swap out different cutting tools, including the boring head, as required by the machining program. This eliminates the need for manual intervention, allowing for uninterrupted machining operations and increased precision.

With an ATC-equipped CNC router, you can program the machine to perform various operations, such as cutting, drilling, and boring, without the need for operator intervention. The machine can automatically change between different cutting tools, including the boring head, based on the programmed instructions.

3This combination of features is particularly useful in applications that require the creation of precise and accurately sized holes or bores in materials. The CNC router can perform the necessary machining operations, including routing, cutting, and boring, with high accuracy and repeatability. It’s important to note that the availability of an auto tool changer and a boring head may vary depending on the specific make and model of the CNC router. It’s always recommended to consult the manufacturer’s documentation or contact the supplier for accurate information regarding the capabilities of a particular CNC router model.

Applications

- Cabinets and Furniture.

- Sign Making and Carving

- Musical Instruments

- Plastic and Foam

- Marble and Stone Engraving

- Prototyping and 3D modeling

- Metal Fabrication and Steel Applications

- Exhibits and Scene / Prop Shops

- Architectural Millwork

- Aluminum and Brass Machining

Suitable Materials:

- Wood: Solid wood, MDF, Plywood, Chipboard.

- Plastic: PVC, ABS, Acrylic, Plastic.

- Marble: Artificial Stone, Marble, Granite, Ceramic,

- Sign Material: Foam, Cupboard, Styrofoam, Leather, Plastic carpet, corrugated paper,

- Metal: Steel, Metal, Stainless, Pipe, tube, Corrugated metals, expanded metal, or flat sheet stock.

- Soft Metal: Aluminum, Brass,

- Composite: Aluminum Composite, Copper Composite, Titanium Composite, Zinc Composite.

Features of ATC CNC Wood Cutting Machine with Drilling Block

- 12HP Air Cooling ATC Spindle, ISO30, ER32.

- Syntec Controller which is a professional for Wood CNC Router with more than 20-year experience, is easy to learn and operate.

- Drive system: 4 Sets AC Servo drivers and 1000W motors for X, Y, and Z-Axis.

- Shimpo Gearbox, much more durable and accurate.

- Helical Rack and Pinion for the X and Y axis to ensure the power transmission.

- High Accuracy ball screw for Z-Axis.

- Rigid Square Linear Guide for X, Y, and Z-Axis.

- Working speed around 25000 mm/min max.

- Traverse speed of rapid feed: max. 60.000 mm/min

- Automatic lubrication system for Linear Guide and ball screw lubrication timely. Thus make sure the CNC Router Machine works smoothly and properly and prolongs the CNC Wood Router life.

- Reference- and limit switch on all axes

- Double safety emergency stop button

- Energy chain for clean cabling

- Milling Motor anchorage: Euro neck Ø43mm

- Compatible with various CAM design software that can output G code or M Code.

- Modular frame for universal application

- Automatical Tool Change function with 12 Pcs tool magazines. Tool Change time can be within 8 seconds.

- Vacuum table in Zones and a powerful vacuum pump to absorb the working piece firmly.

- Dust Collect System with 3.0KW Dust Collector with 2 bags.

- Automatic Tool Sensor.

- Professional Cables and Chains for Wood CNC Router.

- HSD boring block with 9 pcs vertical drill bits.

- C Axis is available

- Aggregate is available

- Safety laser curtain to protect the workers

- Available in 4’x4’, 4’x8’,5×10’, 5’x12′ and Custom Sizes

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.