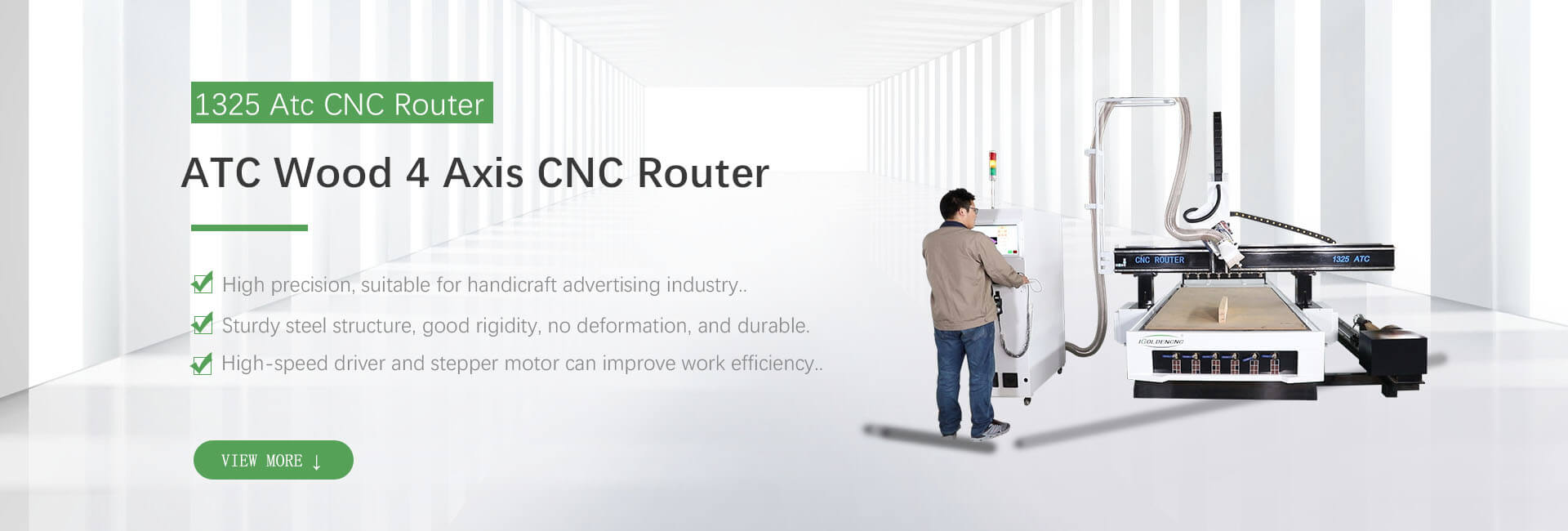

Wood 4 Axis CNC Router

ATC Wood 4 Axis CNC Router Machine ,3D CNC Wood Carving Machine is a combination of 3 axes, 4 Axis, and ATC CNC router. The ATC system adopts an automatic carousel tool changer, which is a faster way to manage tools/bits, this wood CNC machine is a recommended for a long time, heavy-duty, and complex of furniture/doors/cabinet making.

The evolution of woodworking has reached a new frontier with the 4 axis CNC wood router—a powerful, versatile machine that bridges the gap between traditional 3-axis routers and the ultra-complex 5-axis systems. Designed for artisans, furniture makers, and industrial manufacturers, this machine introduces a rotational axis that enables the creation of cylindrical carvings, spiral patterns, and intricate 3D sculptures with precision and repeatability.

ATC CNC Router Video

ATC Wood 4 Axis CNC Router Machine Parameter

Technical Data

| Model | iGW-4AS-LTR 1235ATC |

| Working area | 1300*2500*200mm |

| System | LNC 4-axis system |

| Cabinet | LNC Cabinet |

| Beam | Steel Gantry |

| Countertop | Vacuum suction can suck and clamp the countertop |

| Rail | Taiwan HINWIN |

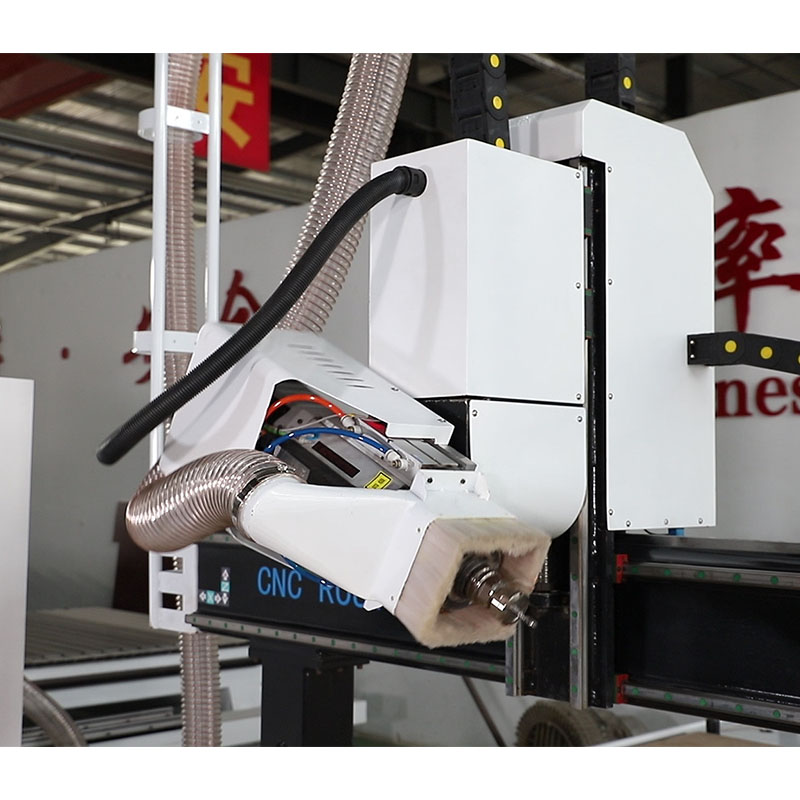

| Spindle | 9KW HQD air cooling spindle ( swing 180°) |

| Drive | Dongling 1.5KW |

| Frequency conversion | Fuling 11KW |

| Voltage | 3phase 380V/60HZ |

| Motor | X/Y axis: Dongling Servo 1.5KW + SHIMPO reducer. Z axis: Dongling Servo 1.2KW + brake |

| Rack | Taiwan xinyue rack |

| Vacuum pump | water-cooled vacuum pump 5.5KW |

| Lubrication system | Automatic lubrication |

| Vacuum cleaner | 3kw double cylinder vacuum cleaner |

If you need more detailed information, please inform us as soon as possible.

ATC CNC Router With Rotary Axis Features

1. Sturdy steel structure, good rigidity, no deformation, and durable.

2. High precision, suitable for handicraft advertising industry.

3. Design: The interface adopts the international standard G code command, which is compatible with domestic and foreign engraving,

and the operation is simple. High quality, reasonable price and economical.

4. High-speed driver and stepper motor can improve work efficiency.

ATC 9KW HQD air cooling spindle, rotate 180 degree

Cycloidal pin wheel precision reducer, with high transmission accuracy and torsional stiffness Can swing from -90 degree to +90 degree.

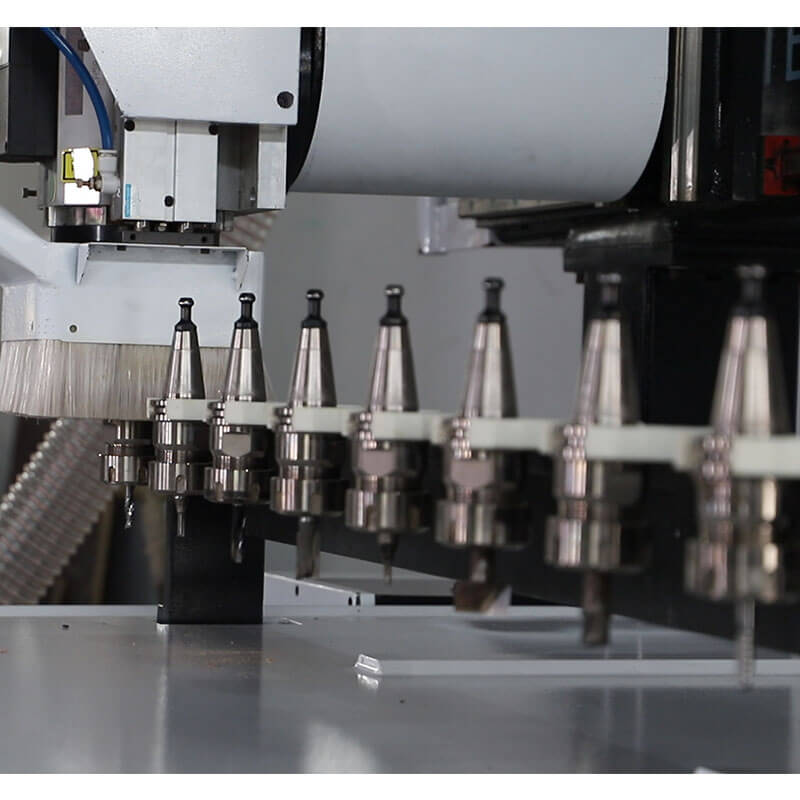

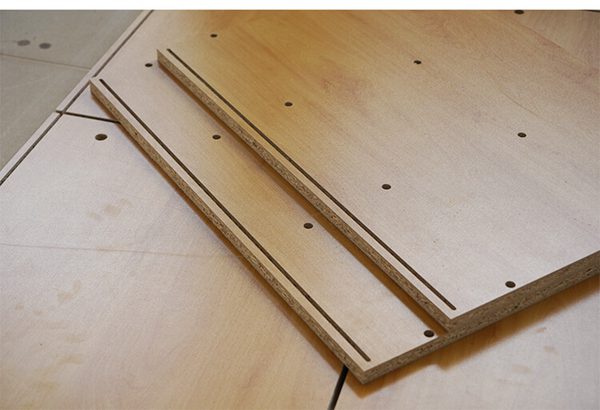

In-line tool change tool magazine

With 8 or 12 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

Tube welding bed

More stable and effectively improves the rigidity and precision of the equipment.

NK280 control system

control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

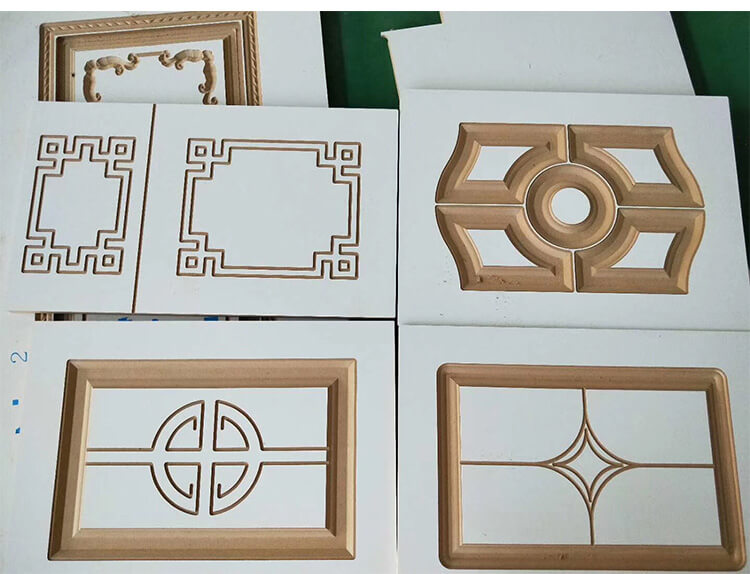

ATC 4 Axis CNC Router Machine Application

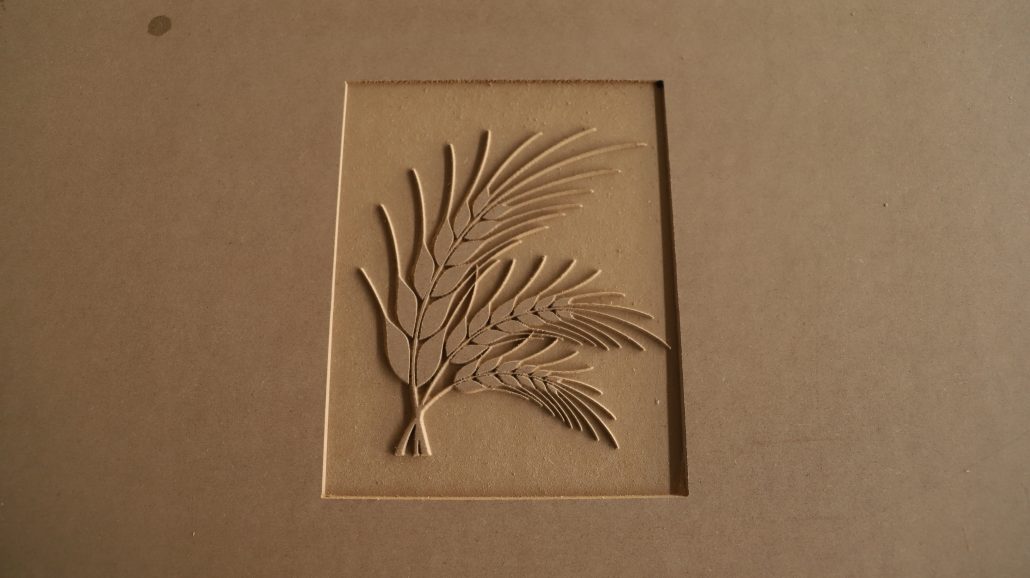

Wooden furniture industry:The 4 axis ATC CNC router here refers to the ATC CNC router with a rotating spindle, which can swing 180° from left to right. The working path of the 4 axis ATC CNC router includes X, Y, Z and A axis. So it is also suitable for cutting and engraving 3D workpieces, such as foam molds, wood and stone sculpture and statues except for the basic applications. In addition, it can also drill side holes or make side grooves or slots on the side of wood panels. The 4 axis ATC CNC router has an extensive use in sculpture and statue making, mold, furniture, decoration, craft, advertising and other fields.

Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

Contact Us Today to Get Price!

Reviews

In the automatic tool changing system, the device that realizes the transfer and loading and unloading of the tool between the magazine and the spindle is called the tool changer. There are two ways to exchange tools: the relative movement of the magazine and the spindle, and the manipulator. The device that uses the relative movement of the magazine and the spindle to realize the tool exchange must first return the used tool to the magazine when changing the tool, and then take out the new tool from the magazine. The two actions cannot be performed at the same time, and the tool change time longer.

However, the manipulator tool changer can grab and load and unload the bits in the spindle and the magazine at the same time during changing, so the changing time is further shortened. The method of tool exchange using a robot is the most widely used. This is because the manipulator is flexible in changing, fast in action, and simple in structure. The manipulator can complete a series of actions such as grasping – drawing – turning – inserting – returning. In order to prevent the bit from falling, the movable claw of the manipulator is equipped with a self-locking mechanism.

1).ATC CNC router generally adopts high-power CNC Router Tool Changer spindle, and the most commonly used ones are 9kw and 12KW spindle. The high-power spindle has fast startup and high torque, which can give full play to the advantages of high speed and high efficiency of high-power tool change spindle.

2).ATC CNC router generally adopts high torque servo motor made in Japan and is equipped with reducer with high reduction ratio. This makes CNC router with tool changer machining center have the advantages of low noise, high speed and high positioning accuracy. 3).Equipped with a unique tool changing device, the required tools can be changed at will, and the special tool setting table can accurately compensate the tool length error. The tool change time of the cnc automatic tool changer is only a few seconds. The standard tool magazine comes with 8 tools, which can customize the tool magazine with larger capacity.